In a groundbreaking advancement that could significantly impact both waste management and climate change mitigation, scientists have developed a method to convert plastic waste into materials capable of efficiently capturing carbon dioxide. The innovative technique, recently reported by Innovation News Network in their article titled “Scientists transform plastic waste into efficient CO2 capture materials,” highlights a promising avenue for repurposing the abundant plastics that pollute our environment.

Led by Dr. Kyra van Hussen and Professor Sergey Alexandrov, researchers at the Plastic Research Center, have successfully taken waste plastics, particularly polyethylene (PE) and polypropylene (PP), and transformed them into porous sorbents. These newly engineered materials exhibit strong potential for capturing CO2 from industrial emissions and the atmosphere, a vital process in efforts to combat global warming.

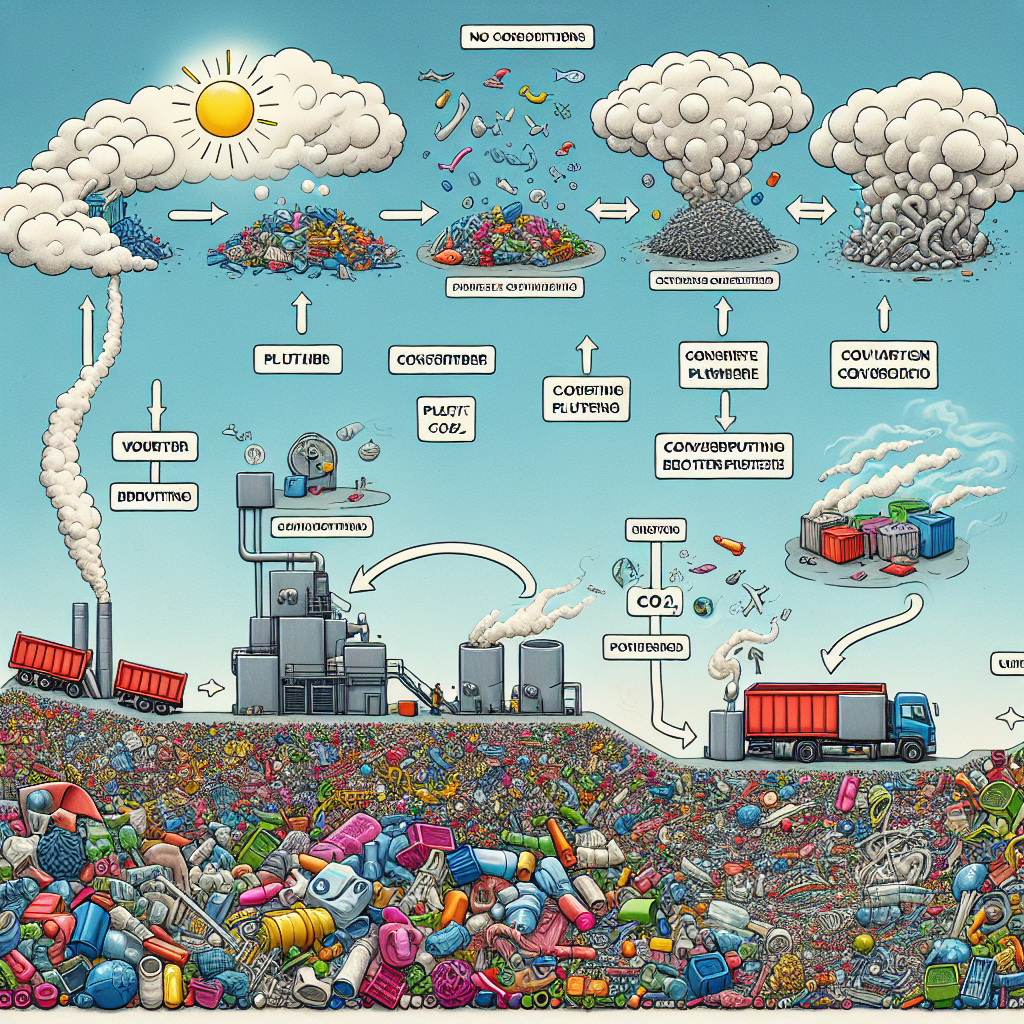

The core of the process involves a chemical transformation known as carbonization, where plastic materials are subjected to high temperatures in the absence of oxygen, converting them into a charred form of carbon with a high surface area. This porous carbon structure is ideal for adsorbing gases such as carbon dioxide. The scientists then enhanced these materials using different amines, chemicals known for their ability to capture CO2, thereby increasing the efficiency of the sorbents.

This process addresses two critical environmental crises simultaneously: the accumulation of plastic waste and the high levels of CO2 emissions contributing to global warming. As Dr. van Hussen explained, “Every year, millions of tons of plastic waste are produced, much of which ends up in landfills or the oceans. By converting this waste into valuable CO2 capture materials, we not only clean our planet but also combat climate change actively.”

The implications of this research are particularly significant for industries such as cement, steel, and chemical manufacturing, which are among the largest producers of carbon dioxide. Integrating this technology could help these industries drastically reduce their carbon footprint by capturing and recycling CO2, potentially turning a harmful waste stream into a circular economic model.

Furthermore, these developments arrive at a critical moment. The fight against plastic pollution has intensified over the past decade, with countries and corporations searching for viable solutions to the ever-growing issue. Similarly, as the effects of climate change become increasingly dire, technologies that can efficiently remove carbon from the atmosphere are becoming crucial.

Another important aspect discussed in the study is the economic viability of this process. The research suggests that transforming waste plastics into CO2 sorbents could be more cost-effective than producing new plastics specifically for the same purpose. Moreover, it utilizes an existing waste stream, which could potentially reduce costs related to waste disposal and management.

The next steps for Dr. van Hussen and her team involve optimizing the conversion process and scaling up production to industrial levels. The challenge will be to maintain efficacy and cost-efficiency while producing sufficient quantities of these sorbents to make a significant impact.

As the world grapples with the twin challenges of waste management and climate change, the work being done by Dr. van Hussen and her colleagues represents a significant beacon of hope. Turning plastic waste into a resource that helps clean the air could be a pivotal strategy in our ongoing environmental efforts, allowing us not only to reuse what we would discard but also to restore the atmosphere for future generations.