A recent breakthrough in regenerative medicine may mark a pivotal advance for tissue engineering and organ repair, thanks to a novel magnetic mixing technology that enhances the preparation of bioinks—key materials in bioprinting. The innovation was detailed in a report titled “Regenerative bioprinting breakthrough: Magnetic mixer enables precise bioink preparation” published by Tech Xplore.

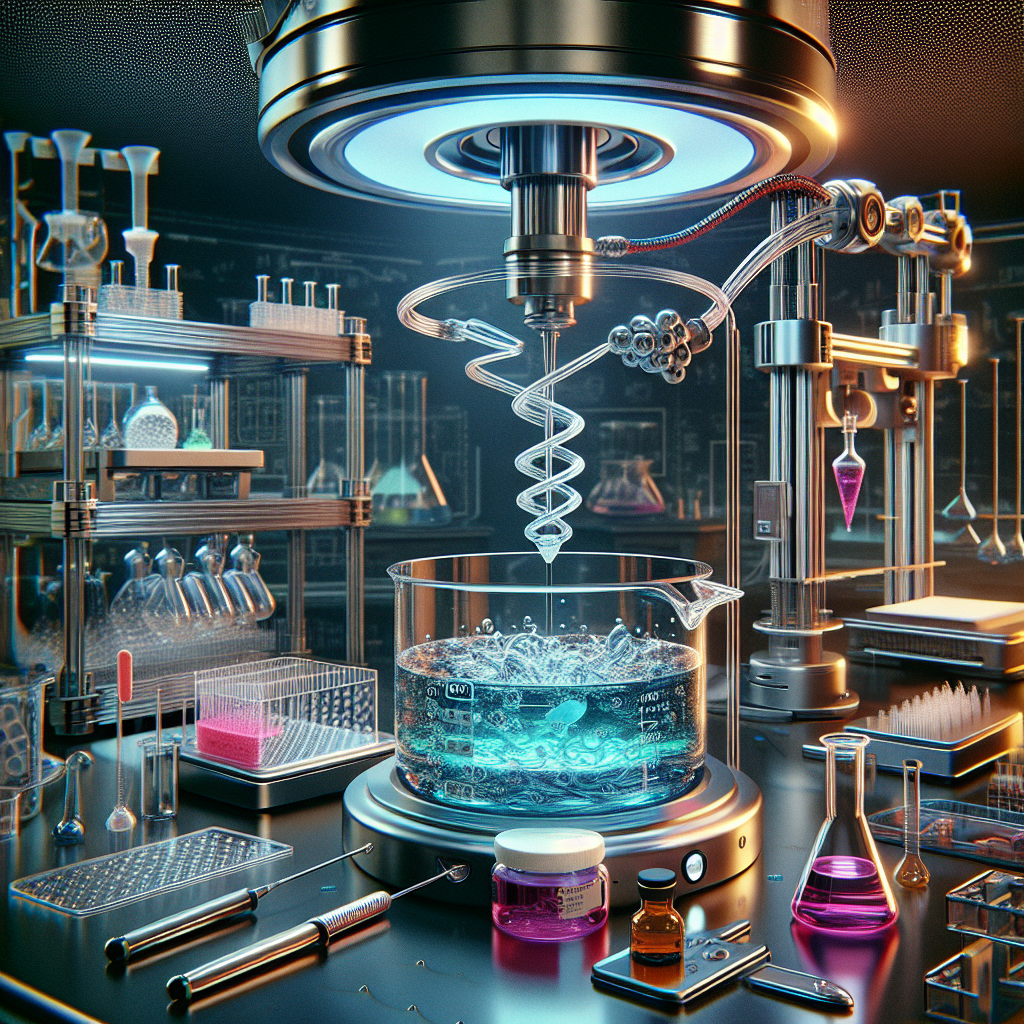

At the core of the development is a magnetic stirrer-based mixer that provides unprecedented precision and consistency in blending bioinks, the gel-like substances laden with living cells used in three-dimensional bioprinting. Developed by a team of researchers specializing in biomanufacturing and biomaterials science, the device addresses one of the field’s major challenges: maintaining cell viability and uniformity during bioink preparation—a critical factor in the quality and function of printed tissues.

Conventional methods of bioink mixing often introduce variables that affect the homogeneity of the cell-laden gels, potentially compromising the structural fidelity and biological activity of the final printed tissue. These inconsistencies can hinder cell growth, morphology, and tissue integration when used for in vivo applications or clinical scenarios. The new magnetic mixing system minimizes mechanical stress exerted on cells during preparation, helping ensure uniform distribution and enhanced cell survival throughout the printing process.

The mixer operates through a dual-axis magnetic drive and is fully enclosed, reducing contamination risks while offering fine control of rotation speed and mixing patterns. This level of control enables researchers to tailor the bioink preparation process according to the specific needs of different tissue types and applications. Early tests demonstrated not only the preservation of cell viability but also improved mechanical characteristics of the bioprinted constructs, such as stability and shape retention.

Industry experts anticipate that this advancement could streamline the development of complex tissue replacements and functional biomaterials for wound healing, cartilage regeneration, and potentially organ fabrication. The system’s scalability and reproducibility could also support wider adoption of bioprinting technologies in both research settings and clinical pipelines.

As the biomedical field increasingly integrates bioprinting solutions into drug testing models and customized therapeutic interventions, technologies like the magnetic mixer may serve as foundational tools. According to the original Tech Xplore article, the researchers believe that refining the physical processes underlying bioprinting—such as material mixing—will be just as crucial as advancing biological formulations.

While further validation, regulatory review, and commercialization steps remain, the introduction of this magnetic mixer marks a significant stride toward more reliable and effective regenerative bioprinting.