Scientists have developed a new artificial intelligence method that could significantly improve the strength and reliability of metal components by identifying stress hotspots at the microstructural level before failure occurs. According to the article “New method uses AI to find stress hotspots in metal microstructures” from Tech Xplore, researchers have harnessed machine learning to predict where mechanical stress is likely to accumulate within metals used in critical infrastructure, ranging from aircraft to power plants.

The innovation comes in response to long-standing challenges in materials science. Despite advances in metallurgy, it remains difficult to anticipate exactly where cracks or weaknesses will appear in metallic parts that undergo significant stress during operation. Even small defects at the microscopic scale can grow over time into critical failures, which can be catastrophic in high-risk applications.

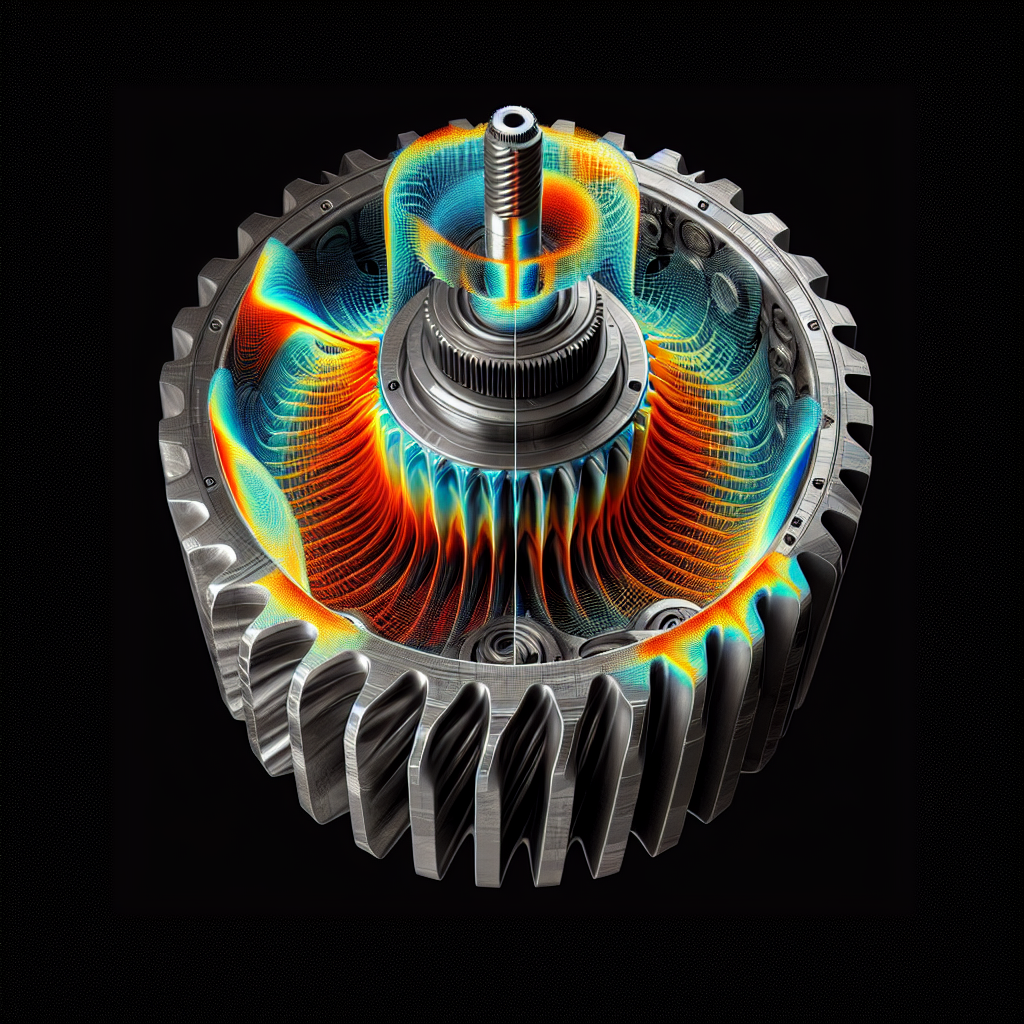

A collaborative team of engineers and computer scientists, led by researchers from Sandia National Laboratories and Purdue University, developed a neural network-based tool that analyzes detailed images of metal microstructures. These microstructures, which emerge during the manufacturing of metal alloys, play a central role in determining a material’s mechanical performance. By training their AI system on simulation data representing tens of thousands of stress scenarios, the researchers created a model capable of predicting the specific regions where a material is most likely to experience high levels of stress under various loading conditions.

The key to the method’s success lies in its ability to incorporate realistic representations of grain boundaries and phase distributions—features that are difficult to characterize comprehensively using traditional models. Previously, the computational effort required to analyze microstructural behaviors at this scale was often prohibitive, limiting the scope of such predictions to small datasets or simplified models. The new AI approach significantly reduces the computational burden, making it possible to analyze entire components more efficiently and in greater detail.

The team validated their model using simulations of a common nickel-based superalloy, a material widely used in jet engine turbines and other high-temperature environments. The neural network successfully predicted the most vulnerable regions within the alloy’s complex geometry, offering insights that align with physical theories but were previously too computationally intensive to verify broadly. Researchers believe the method can be generalized to a wide variety of metallic systems.

These findings could have far-reaching implications for both the design and maintenance of critical infrastructure. By pinpointing stress-prone regions before components are manufactured—or while they are still in early stages of wear—engineers can tailor materials and designs to prevent premature failure. This new level of predictive insight could lead to safer, longer-lasting components and improved life-cycle performance of high-stress systems.

As the article from Tech Xplore notes, the research is not only a technological milestone but also a sign of how machine learning continues to redefine the boundaries of engineering. By combining high-fidelity physics simulations with advanced AI techniques, scientists are bridging fundamental science and applied materials design, opening new avenues for innovation in aerospace, energy, and transportation industries.