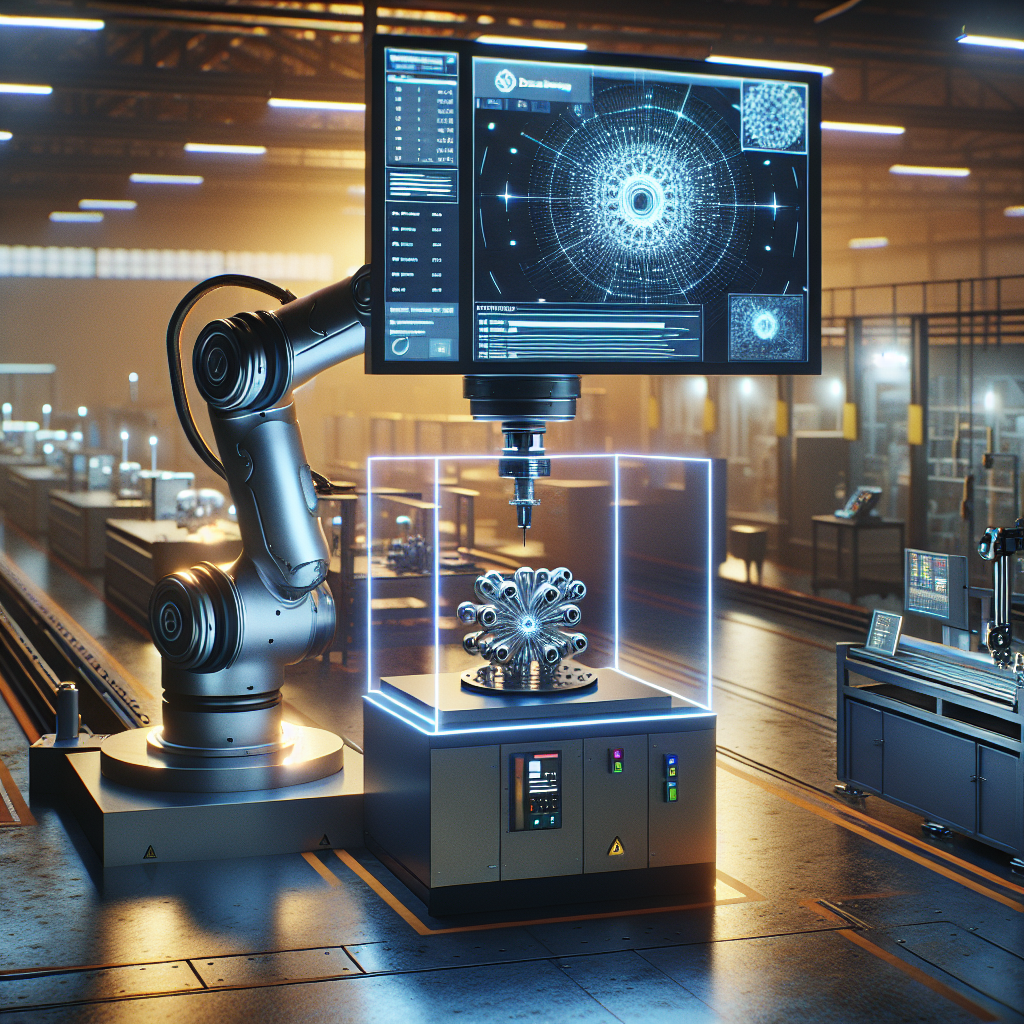

A new frontier in quality assurance for advanced manufacturing has emerged with the development of an artificial intelligence system capable of detecting internal defects in 3D-printed metal parts as they are being produced, potentially revolutionizing industrial production processes. The breakthrough, detailed in the article “AI spots 3D printing defects in real time” published by Tech Xplore, highlights a major advancement in the pursuit of safer and more reliable metal components for critical industries like aerospace, automotive, and biomedical engineering.

The innovation centers on the use of computer vision and machine learning algorithms to monitor 3D printing processes in real time, identifying anomalies that could signal material weaknesses or performance failures before the item is completed. Traditional methods of quality control often rely on post-production inspection techniques, such as X-ray scanning or destructive testing, which can be both time-consuming and expensive. This new AI-driven approach offers a faster, more efficient alternative that reduces waste and enhances safety.

The AI model was trained on data generated during laser powder bed fusion, a common method for producing metal parts layer by layer. By analyzing thousands of images taken during the printing process, the system learned to associate certain visual cues with the presence of defects such as voids, cracks, or incomplete fusion. When deployed, the AI can now flag potential issues as they arise, allowing manufacturers to halt production or modify parameters mid-process to prevent defective outputs.

Researchers behind the project emphasized the broader implications of real-time defect detection. Since manufacturing errors in mission-critical sectors can have catastrophic consequences—from structural failures in aircraft to malfunctions in medical devices—the ability to ensure part integrity from moment to moment is a significant leap forward. Moreover, the technology may enable wider adoption of metal additive manufacturing by improving confidence in the consistency and safety of printed parts.

While the current model is focused on a specific 3D printing technique, the team envisions adapting it for other additive manufacturing systems and diverse material types. With further development, the technology could be integrated directly into commercial printers, offering manufacturers a turnkey solution for in-situ quality assurance.

The research reflects a broader trend in manufacturing toward the integration of artificial intelligence and automation to improve productivity and reduce human error. As AI systems become more sophisticated and accessible, their role in ensuring the precision and safety of complex manufacturing processes is likely to expand significantly in the coming years.