In a significant advancement for additive manufacturing, researchers have successfully 3D-printed one of the hardest materials known to science—boron carbide—marking a potential turning point for high-strength industrial and defense applications. The achievement was detailed in a recent article titled “Engineers successfully 3D print one of industry’s hardest materials” published by Tech Xplore.

Boron carbide, often referred to as “black diamond,” has long been a material of interest due to its exceptional hardness, high melting point, and resistance to chemical attack. These properties make it invaluable for use in armor plating, nuclear shielding, abrasives, and wear-resistant components. However, its inherent brittleness and extreme processing requirements have presented major obstacles to traditional manufacturing methods and additive fabrication alike.

The breakthrough, led by engineers at the University of California, San Diego, was accomplished using a novel technique that combines a preceramic resin and lithography-based ceramic manufacturing. This approach allowed the team to bypass the typical challenges associated with sintering boron carbide powders, including high temperatures and problematic grain growth that often compromise the material’s mechanical properties.

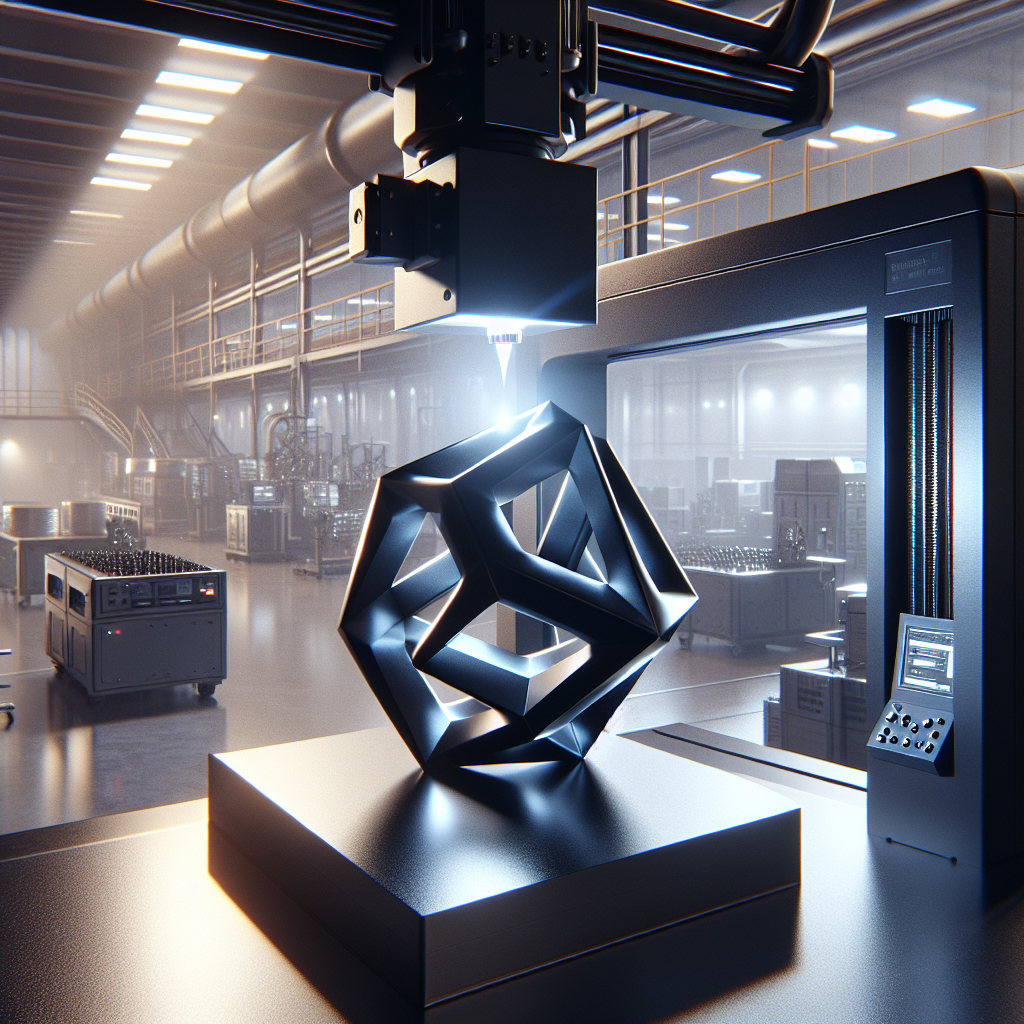

By enabling the production of complex geometries that maintain the material’s structural integrity, the new method opens the door to customized, lightweight, and high-strength components not previously feasible. These could include intricate armor systems, advanced protective coatings, and potentially even more durable materials for space and aerospace engineering.

The improved process involves stereolithography to shape ceramic precursors into desired forms, followed by pyrolysis—a high-temperature thermal processing stage to convert the resin into dense boron carbide. The researchers reported achieving hardness values comparable to traditionally manufactured boron carbide, all while reducing time and material waste.

What makes this development particularly noteworthy is its implications for industries where the balance between weight and durability is critical. The military, in particular, could benefit from lighter ballistic armor, while manufacturers of industrial machinery could gain access to more precise and abrasion-resistant components.

The team emphasized that while further refinement is needed for scaling and mechanical consistency, the success demonstrates that even the industry’s hardest materials are viable for additive manufacturing through innovative chemical and photopolymer engineering.

As additive manufacturing continues to mature, the ability to 3D print such advanced ceramics suggests a future in which high-performance materials can be rapidly prototyped, customized, and deployed across a range of demanding applications. The work not only underscores the technological progress being made in materials science but also paints a promising picture of the growing convergence between digital manufacturing and extreme-performance materials.