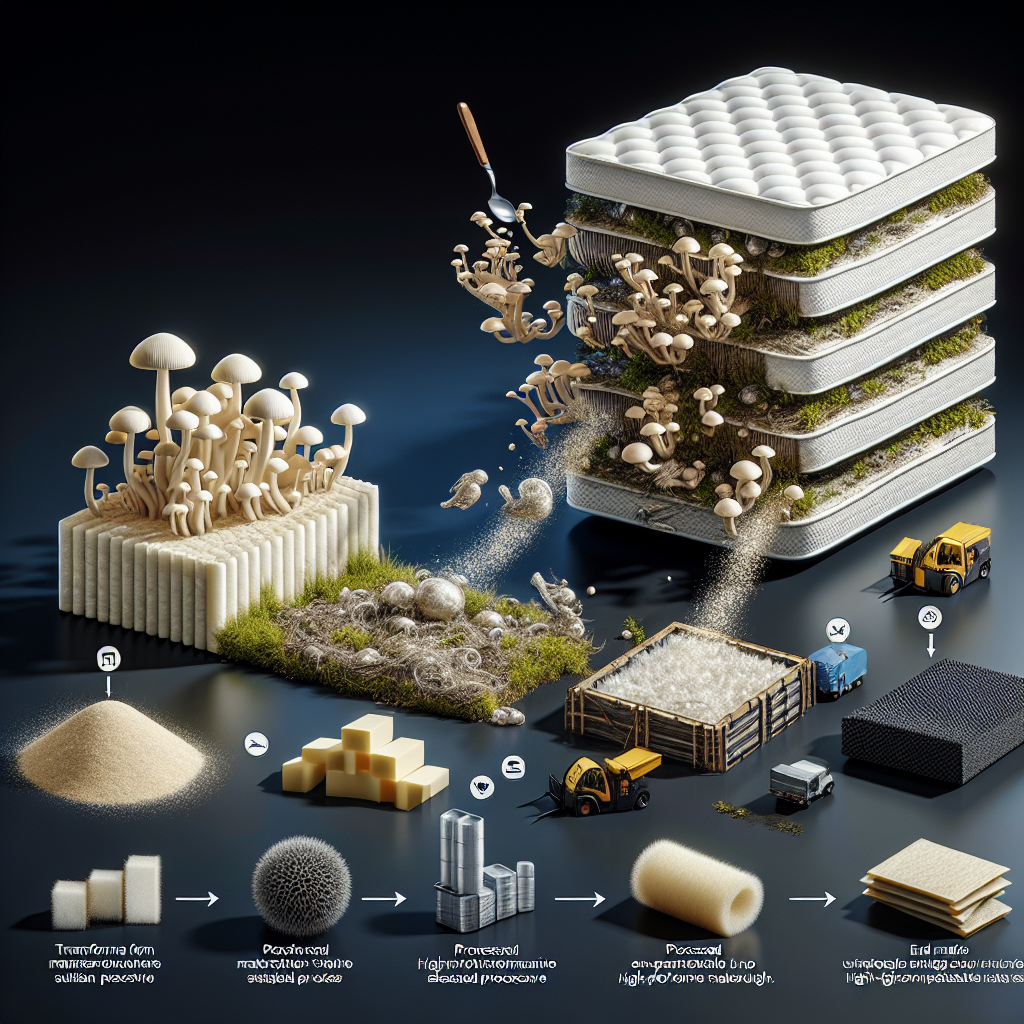

In a promising development for sustainable materials science, researchers have demonstrated that fungi can transform shredded mattress foam into lightweight, high-performance materials suitable for construction and protective gear. The findings, originally reported in the article titled “Fungi turn shredded mattress foam into useful lightweight parts” by Tech Xplore, point to an innovative method for upcycling polyurethane waste, a notoriously difficult-to-recycle material prevalent in consumer products.

The research, led by a team of scientists from the University of Queensland, leverages the natural capability of fungi to feed on complex carbon-based compounds. Specifically, the mycelium—the fast-growing root structure of fungi—was cultivated on shredded polyurethane foam. Over several days, the fungi colonized the waste material, binding it into durable, flexible structures. The resulting composite not only retains the resilience of the original foam but also boasts enhanced mechanical properties such as shock absorption and thermal insulation.

These bio-fabricated materials could have wide-ranging applications, from cushioning in protective sportswear to insulation panels in sustainable architecture. Notably, the method requires minimal energy input and avoids the use of harmful solvents or synthetic binders, significantly reducing the environmental footprint compared to conventional plastic recycling or manufacturing processes.

Polyurethane is commonly used in mattresses, upholstery, and automotive seats, yet its complex chemical composition makes it largely incompatible with traditional recycling streams. Much of it ends up in landfills or is incinerated, contributing to mounting environmental concerns. By enlisting fungi as a biological recycler, the researchers offer a pathway to not only divert such waste but also generate value-added products.

In lab tests, the research team experimented with various fungal strains and foam fragment sizes to optimize growth and material consistency. They reported that certain fungi were more efficient at metabolizing the foam and producing strong, cohesive composites. Once dried, the mycelium-infused foam retained a low density akin to that of conventional lightweight polymers while outperforming them in sustainability metrics.

The study underscores the growing scientific interest in mycelium-based materials, which have previously been investigated for uses ranging from packaging to building bricks. However, utilizing discarded polyurethane in the matrix marks a notable advancement, combining waste mitigation with next-generation materials engineering.

While the technology is still in its early stages, the researchers are optimistic about scaling the process. They envision partnerships with recycling centers, manufacturers, and municipalities to establish localized fungi-based recycling facilities. Regulatory approvals and performance certifications will be crucial in bringing such eco-friendly innovations to market.

The team’s work contributes to a broader shift in materials science, where biological processes are increasingly harnessed to address environmental degradation and resource scarcity. As industries and governments grapple with the urgent need to reduce plastic pollution, the fungal approach presented in Tech Xplore’s article adds an intriguing tool to the growing arsenal of green technologies.