A new generation of titanium 3D printers is poised to reshape the aerospace manufacturing sector, offering transformative improvements in both production efficiency and material performance. According to a recent article titled “Titanium 3D Printer Improving Aerospace Manufacturing” published by StartupNews.fyi, groundbreaking advancements in additive manufacturing are enabling companies to produce stronger, lighter, and more complex components at unprecedented speed and reduced cost.

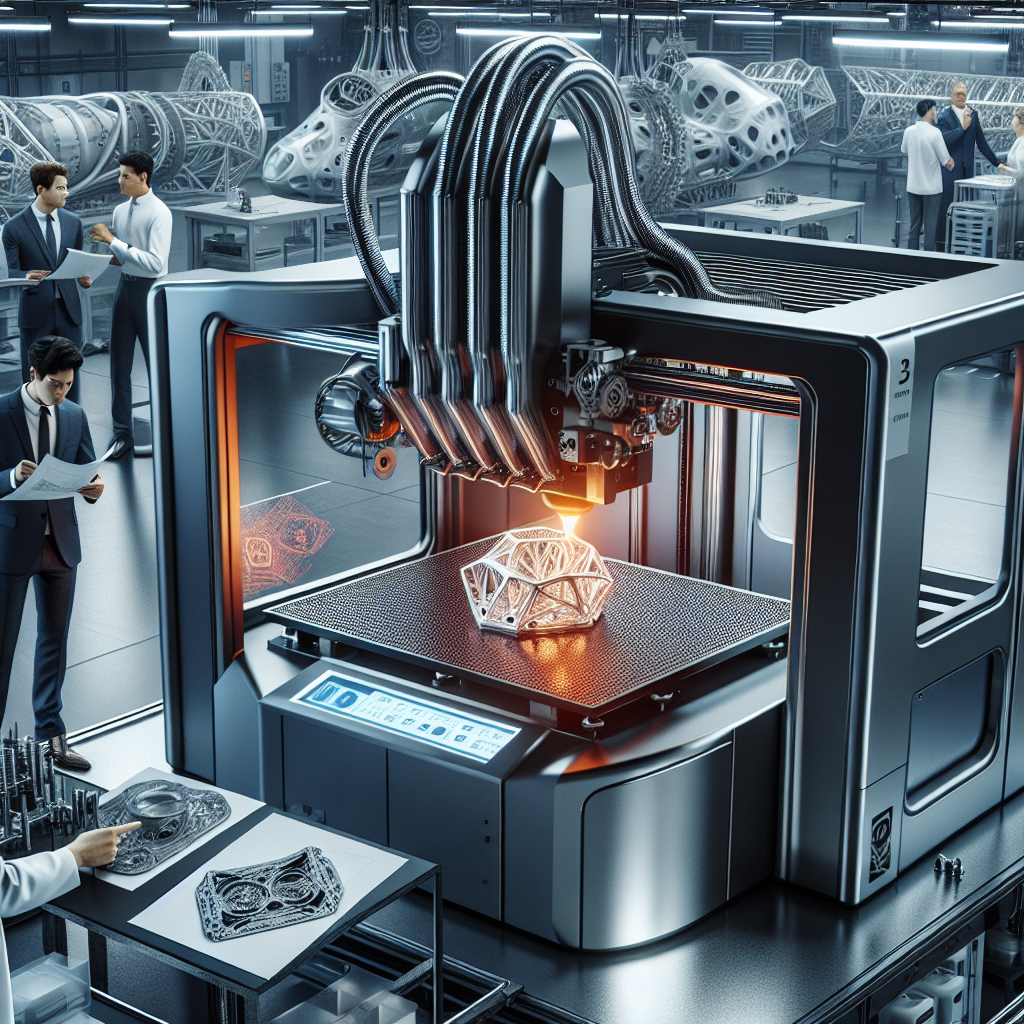

The technology, developed by a consortium of engineers and materials scientists, leverages a refined powder-bed fusion process to fabricate titanium parts with geometries previously deemed too intricate for conventional manufacturing. Titanium, long prized in aerospace for its high strength-to-weight ratio and corrosion resistance, has traditionally been difficult and expensive to machine. The new 3D printing capabilities aim to overcome these barriers by directly building components from metal powders layer by layer, minimizing material waste and tooling requirements.

According to StartupNews.fyi, this innovation is not only reducing lead times but also enabling manufacturers to consolidate what were once multi-piece assemblies into single, monolithic parts. The result is a dual benefit for the aerospace industry: lighter aircraft structures and enhanced operational durability. Industry experts note that such developments are particularly attractive in the context of increasing demand for fuel-efficient aircraft and the growing ambitions within space exploration.

Leading aerospace firms are already beginning to adopt these printers for both prototyping and end-use production. In particular, engine manufacturers are exploring ways to fabricate turbine components and structural brackets with increased thermal performance and fewer failure points. This shift underscores a broader industry trend toward digital transformation and agile manufacturing processes.

However, challenges remain in scaling the technology. Quality assurance, standardization of materials, and regulatory certification processes are still catching up with the pace of technological progress. Additionally, high power requirements and the need to manage micron-level precision in powder metallurgy continue to pose engineering hurdles.

Still, the promise of titanium 3D printing is compelling. As noted in the original article on StartupNews.fyi, the integration of these advanced printers into commercial aerospace supply chains could mark a significant turning point for an industry traditionally defined by long production cycles and inflexible manufacturing paradigms.

With sustained investment and further refinement, additive manufacturing using titanium could well become the backbone of next-generation aircraft and spacecraft development. As aerospace manufacturers seek to meet rising global demand while improving efficiency and sustainability, the adoption of this technology seems not only inevitable but essential.