In a development poised to reshape the future of engineering, robotics, and manufacturing, scientists have unveiled a breakthrough material capable of transforming into a wide array of objects and shapes through a simple mechanical operation. As reported in the article “Scientists Make Material That Can Morph Into Anything With the Pull of a String,” published by StartupNews.fyi on December 27, 2025, researchers have created a programmable structure that changes geometry when tensioned, suggesting unprecedented adaptability in material design.

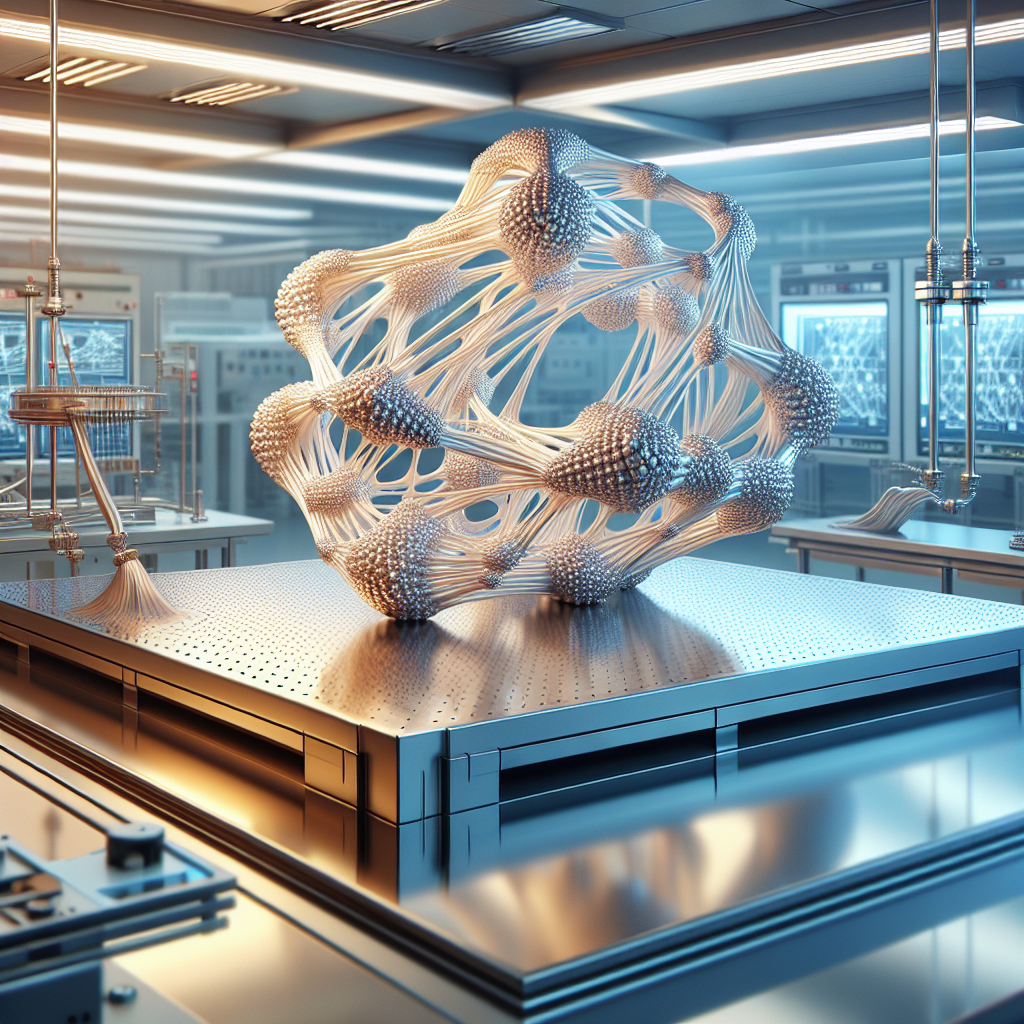

The innovation centers on a lattice-like structure composed of modular components that shift in response to controlled tension. By pulling a string embedded within the material, the structure can morph into predefined configurations—a chair, a drone casing, or even a robotic appendage—without the need for motors or electronic controls typically used in shape-change technologies.

According to the research team, this tactile actuation method represents an elegant solution to a complex problem: how to achieve shapeshifting capabilities while minimizing energy input and mechanical complexity. What sets this new material apart is its reliance on mechanical design principles rather than active electrical components, making it lightweight, scalable, and potentially more durable in extreme conditions.

The research, conducted by an interdisciplinary group of engineers and material scientists, involved manipulating architectural geometry at the microscale to create adaptable units that maintain strength and stability in both their static and dynamic states. The outcome is a programmable system that requires only a predetermined pulling sequence to morph from one form into another.

The implications of the technology are broad. In industrial settings, such materials could allow a single item to serve multiple structural or functional purposes, significantly streamlining logistics and reducing material waste. In aerospace and defense, compact structures that expand into full-sized components on demand could revolutionize portable equipment design. The healthcare industry may also find applications in prosthetics or adaptive medical supports that conform to a patient’s changing needs.

While still in its early stages, the technology has already passed a series of proof-of-concept tests, including successful shape transitions among more than a dozen geometries. The team is now working on enhancing the material’s resilience and exploring self-deploying mechanisms that respond to environmental cues rather than manual inputs.

Despite the enthusiasm, researchers caution that commercial deployment may still be several years away. Challenges remain, particularly in scaling production and ensuring reliability under repeated actuation cycles.

Still, the innovation reported by StartupNews.fyi signals a potential paradigm shift in how objects are assembled, used, and perceived. As the boundary between material and machine continues to blur, developments like these suggest a future in which everyday items adapt to changing contexts with the simplicity of pulling a string.